Abstract

This work seeks to produce wood-based panels with Amazon wood sawing residues and castor oil-based polyurethane resin as binder. Three types of panels were produced, with the following resin proportions: 25%, 30%, and 35%. Physical and chemical tests were performed to assess the potential for using this residue, and physical and mechanical properties of the panels were evaluated. Tukey test was performed with a 5% probability to verify the significance between the means for the different types of panels. The results show that the produced panels have a high density (~800 kg/m3), modulus of rupture (~11 N/mm2), which meet the physical properties and modulus of rupture (Non-structural) required by Brazilian particleboard standards, demonstrating its potential in the use of non-structural panels in furniture or finishing. However, the panels did not meet the modulus of elasticity (~900 N/mm2) property, indicating the need to propose ways to improve this property in such panels in future research

Keywords

Amazon; Composite; Polyurethane; Residues; Wood

Resumo

Este trabalho produziu painéis derivados de resíduos de serragem de madeira amazônica e resina poliuretana à base de óleo de mamona como ligante. Foram produzidos três tipos de painéis, com as seguintes proporções de resina: 25%, 30% e 35%. Foram realizados testes físicos e químicos para avaliar o potencial de aproveitamento desse resíduo, assim como foram aferidas as propriedades físicas e mecânicas dos painéis. O teste de Tukey foi realizado com 5% de probabilidade para verificar a significância entre as médias para os diferentes tipos de painéis. Os resultados indicam que os painéis produzidos possuem alta densidade (~800 kg/m3) e um módulo de ruptura (~11 N/mm2) que atendem aos requisitos físicos e ao módulo de ruptura (não estrutural) exigidos pela norma brasileira de painéis de partículas, demonstrando seu potencial na utilização em móveis ou acabamentos não estruturais. No entanto, os painéis não atenderam ao requisito de módulo de elasticidade (~900 N/mm2), indicando a necessidade de propor formas de melhorar esta propriedade em tais painéis em pesquisas futuras.

Palavras-chave

Amazônia; Compósito; Poliuretana; Resíduos; Madeira

Introduction

Brazil is one of the largest wood producers in Latin America and the largest producer of tropical logs (ITTO, 2019). Brazil has a large diversity of wood species, with 8.715 high-quality species (Beech et al., 2017). Given the increase in exports of tropical wood products and ongoing concerns about deforestation and unsustainable forest management practices in the Amazon region, production levels have increased (ITTO, 2019).

Conversely, since at least 40% of logs are wasted, problems arise in generating residues due to outdated technology processes (Silva et al., 2016). With this low efficiency, generating wood residues becomes an obstacle to sustainable development (Ramos et al., 2017). Because these wastes are used to produce energy, they contribute to environmental problems, leading to the production of ash and gases (de Souza et al., 2018).

The utilization of Amazonian wood residues is currently low, with inappropriate disposal methods, yet they hold potential for products with higher value, such as particleboards (Surdi et al., 2019; dos Santos et al., 2023). Agglomerated wood-based panels are produced from particles of sawmill residues, logs, or other wood types bonded together using resin under heat and pressure. There are studies on using these residues for producing such panels, which can have adequate properties such as low thickness swelling (Sugahara et al., 2022).

For its manufacture, Pinus and Eucalyptus species are the most common basic raw materials (Faria et al., 2021; Pedzik; Janiszewska; rodozinski, 2021). However, research should be carried out on the feasibility of using alternative species, such as tropical wood residues, for the production of particleboards (Iwakiri et al., 2016) since the high availability of wood residues in the Amazon region can be an alternative for the panel industries (Surdi et al., 2019).

Iwakiri et al. (2016) assessed the quality of panels produced with residues from some Amazonian species, including Scleronema micranthum ducke (cardeiro), Ecclinusa guianensis Eyma (caucho), Scleronema sp. (castanha de paca), and Copaifera multijuga Hayne (copaíba). They inferred the technical feasibility of using those species in producing particle board panels since they presented good mechanical properties, such as perpendicular tensile stress, which meet the minimum requirement of the European standard EN 312 (ECS, 2003).

Zau et al. (2014) produced panels using residues from the Dipteryx odorata (cumaru) Amazonian wood. They inferred that panels with 1500 grams residue content and 10% and 15% castor oil-based polyurethane (PU) adhesive resin achieved better mechanical properties (for example, modulus of rupture), higher than the minimum specified by the NBR 14810-2 standard (ABNT, 2018), showing potential to be used in producing these panels.

Sugahara et al. (2019) produced particleboards using particles from Eucalyptus residues (from the mechanical processing of wood in a pulp and paper mill) and sugarcane bagasse, with either castor oil-based PU resin and urea-formaldehyde (UF) resin as the binder. The particleboards comprised 60% wood particles and 40% bagasse, with 10% binder. The particleboards using either resin had high density, and, according to the NBR 14810-2 standard (ABNT, 2018), they belong to type P4 (structural panels for use in dry conditions). The panels using PU resin achieved better mechanical properties when compared with the UF resin, as well as thickness swelling. Also, PU did not emit formaldehyde during the pressing process, which is better for the environment.

Dos Santos et al. (2023) investigated the effects of mercerization and moisture levels of two types of Amazon tropical wood (massaranduba and louro gamela) on polymeric composites. NaOH concentration modifies the wood residues’ thermal, structural, and morphological characteristics. However, these modifications were more effective in the composite when the moisture content of the fibers was low.

De Souza et al. (2022) studied single-layer (homogeneous) and three-layer (heterogeneous) particleboards composed of Tectona grandis wood particles using castor oil-based PU resin as the binder. The resin proportions were 10% for the single-layer particleboards and 12% for the three-layer particleboards, and the latter had finer particles in the outer layers. Thickness swelling and water absorption properties were better for the three-layer particleboard. The density for the three-layer particleboard was close to the maximum value recommended by the NBR 14810-1 standard (ABNT, 2013) for medium-density panels.

A search on the Web of Science platform (publications up to August 2024) reveals only 24 results combining the keywords “tropical wood waste” AND “polyurethane” AND “castor oil.” This highlights the lack of studies on the use of tropical wood residues associated with castor oil-based resins, a highly relevant and emerging topic. In contrast, countries like Italy, Denmark, and the United Kingdom reuse 95%, 67%, and 53% of wood waste, respectively, in the production of particleboard (Meinlschmidt; Mauruschat; Briesemeister, 2016). In Sweden, for example, it is necessary to import wood residues from Norway to meet the goal of producing 30% of panels with recycled materials (Elginoz et al., 2024).

Our study aims to fill the knowledge gap regarding the feasibility of using Amazonian wood residues for panel production, particularly considering the possibility of using different particle sizes and resin percentages. Varying particle size allows for greater utilization of the residue, promoting a more sustainable approach. Although Zau et al. (2014) investigated the use of cumaru tropical wood residues in the production of panels with 10%, 12.5%, and 15% resin content, his research was limited to a single particle size.

Moreover, most studies focus on the use of resins such as urea-formaldehyde (Iwakiri et al., 2016) or on non-tropical wood species (Sugahara et al., 2019), emphasizing the importance of the obtained results for the development of new materials applicable to the Brazilian civil construction and furniture industries. By exploring the potential of tropical wood residues combined with sustainable resins, our work contributes to the advancement of innovative and environmentally responsible solutions in the particleboard sector.

This study addresses this gap by assessing the viability of using unprocessed wood mix residues from the Amazon rainforest for sustainable panel production. To achieve this, a blend of sawdust from different wood species was utilized in panels bonded with castor oil-based polyurethane resin, enabling the evaluation of their physical and mechanical properties. Notably, no previous studies have attempted to produce and evaluate the properties of such panels derived from different woods, thus offering a sustainable alternative for industries in this sector.

Materials and methods

Materials

Castor oil-based polyurethane resin (from Iperveg, type AGT1315) was used, composed of pre-polymer and polyol (Sugahara et al., 2019), resulting in polymers with exceptional physical-chemical stability, elasticity, and impermeability.

The sawdust was obtained in a sustainable sawmill in the city of Itacoatiara in the State of Amazonas, Northern Brazil. The residues are made up of different types of high-quality tropical species produced exclusively from Amazonian rainforest wood from the sawing process (Table 1). Sustainability in the extraction and use of these woods is crucial to ensure the preservation of these species and the integrity of forest ecosystems.

Method

In order to understand the chemical, physical, and thermal characteristics of the sawdust mixture, the following characterizations were carried out:

The elemental composition was obtained through the X-ray fluorescence (XRF) spectrometry technique using a PANalytical Epsilon3-XL spectrometer with 15 W maximum power. In this test, 10 g of sawdust were used to identify the elements present in the material.

Moisture content was obtained by measuring the percentage of mass loss at a temperature of 100 °C for 15 minutes by the OHAUS MB35 halogen moisture analyzer (Fan; Nagaraj, 2012). Samples of 0.5 grams were used for this test.

The ash content was compliant with the T211 om-02 standard (TAPPI, 2002a). The acid-insoluble lignin content was determined according to TAPPI T222 om-02 standard (TAPPI, 2002b), using 72% sulfuric acid. The extractives content was determined based on the TAPPI T204 cm-97 standard (TAPPI, 1997), using ethanol-toluene solution (1:2). The cellulose content was analyzed according to the methodology proposed by Leão (2008), using nitric acid-acetic acid solution (1:8) ethanol.

The thermal degradation of the wood was obtained through a thermogravimetry test using a TA Instruments device, SDT Q600 model with DSC-TGA module standard. The sample was heated from room temperature to 700 °C with a heating rate of 10 °C/min in a nitrogen atmosphere, with 100 ml/min airflow.

Panel production

Two types of sieves were used: 20 mesh (granulometry equal to 0.85 mm) and 8 mesh (granulometry equal to 2.38 mm). The panels were produced using the following particle sizes:

-

passed through the 20-mesh sieve;

-

retained in the 20-mesh sieve; e

-

retained in the 8-mesh sieve.

Three types of panels were produced with the following contents of castor oil-based polyurethane resin in a 1:1 ratio: 25%, 30%, and 35%, based on the dry weight of the particles. These values were determined from studies by Nogueira, Lahr and Giacon (2018). The dimensions of the panels were 280x280x10 mm, and the target density was 800 kg/m³.

The sawdust particles were dried in a furnace (model Ethik Technology - https://www.ethik.com.br/produtos/?ucterms=product_cat~estufas) at a temperature of 70 °C for 6 hours, seeking to reduce moisture up to 9.34٪, an accepted value for using the polyurethane resin (Dias, 2005).

To produce the panels, the process involved adding the resin manually to the particles. Subsequently, the material was placed in a mold (280 mm x 280 mm x 10 mm) and underwent manual pre-pressing. This step aimed to enhance compaction, reduce volume, and minimize the occurrence of voids. Then, the material was pressed at the HIDRAL-MAC hydraulic press at 100 °C, with a pressure of 10 MPa for 10 minutes (Bertolini et al., 2013). The produced panels remained at room temperature for approximately 72 hours to cure the polymeric material and stabilize the composite.

Panel characterization

Physical tests, including assessments of density, moisture content, thickness swelling, and water absorption, as well as mechanical tests, such as static bending and screw pullout, were conducted according to NBR 14810 (ABNT, 2018) to evaluate the potential utility of the particleboard panels manufactured in this study. Additionally, micrographic analyses were performed to examine the panels’ properties further.

To determine the modulus of rupture (MOR) and the modulus of elasticity (MOE), bending tests with a three-point test configuration were performed in an Oswaldo Filizola universal testing machine, AME model, with a capacity of 5 kN. The tests were performed based on the NBR 14810-2 standard (ABNT, 2018).

For the top and surface screw pullout strength tests, the samples had dimensions 50x50 mm. Ten specimens were used for the top pullout strength tests, and ten specimens for the surface screw pullout tests were taken from the produced panel. The tests were carried out using the INSTRON 5984 universal testing machine.

Scanning electron microscopy (SEM) was performed using the VEGA 3 (TESCAN) equipment, 51-ADD0007 model, to analyze the rupture region’s morphology from panels. The dimensions of the samples were equal to 5x5 mm and dried in a furnace to eliminate moisture. Samples were placed in a piece of equipment for coating by dispersion of gold metallic ions and analyzed by SEM, aiming to improve the contrast and maximize resolution (Dedavid; Gomes; Machado, 2007).

Tukey test was performed with 5% probability (Montgomery, 2017) to verify the significance level between the means of the physical and mechanical properties obtained for the different types of panels.

Results and discussion

Chemical and physical properties of the sawdust

X-ray fluorescence (XRF) was performed on the sawdust; the results are shown in Table 2. There was a predominance of Iron (Fe) (27.41%), calcium (Ca) (26.97%), silicon (Si) (16.08%), and aluminum (Al) (8.51%). Additionally, Silicon dioxide (SiO2), Calcium oxide (CaO2), and Iron (III) oxide (Fe2O3) were present in percentages of 24.52%, 22.59%, and 21.42%, respectively.

Iron contributes to reddish tones in the burned parts, while calcium enhances strength against sudden temperature changes (Inocente et al., 2017). The presence of silica (SiO2) can improve the quality of the material, especially mechanical strength, by providing greater rigidity to the cell walls. It should be noted that the composition of residues is directly linked to the soil region and also inherent to climate and surroundings (Rebelo et al., 2019).

Moisture content was 14.62%. However, this value exceeded the recommended content by Dias (2005), who suggested one moisture content ranging between 8% and 12% when using polyurethane as a binder. Therefore, the particles were dried in a furnace at 60 ºC for 6h, resulting in a moisture content of 9.34٪.

Ash content was determined through three measurements, yielding a mean of 1.97% and a standard deviation of 0.38%. This ash content aligns closely with the 1.72% found in cumaru wood (Dipteryx odorata), as reported by Zau et al. (2014), and higher than the 0.598% of massaranduba wood obtained by Lira, Silva and Andersen (2014). The latter authors note that higher values are typical in tropical woods, which can contain up to 5% ash, and that this content may vary based on soil characteristics, harvesting methods, and surrounding environments.

Three measurements were conducted for the following contents:

-

extractives (mean = 13.32%, standard deviation = 0.0%, i.e., no variation between samples up to the fourth decimal place);

-

lignin (mean = 49.32%, standard deviation = 3.72%); and

-

cellulose (mean = 41.11%, standard deviation = 0.14%).

The extractives content (13.32%) is lower than that reported by Zau et al. (2014) (18.32%). According to César et al. (2017), waxes and extractives can decrease the matrix/fiber adhesion. Conversely, Iwakiri et al. (2016) obtained values for extractives ranging from 3.16% and 9.24% for the Pouteria guianensis and Amazonian Manilkara tropical woods, respectively, inferring that for these lower values, extractives did not significantly affect particle adhesion.

Poletto, Ornagui Júnior e Zattera (2014) observed that tropical woods such as Dipteryx odorata and Mezilaurus itauba had extractives content three times higher than temperate species such as Eucalyptus grandis (flooded gum) and Pinus elliottii (slash pine). The difference in the content of extractives is explained by the heterogeneity of the material, with different wood species and ages, as well as the influence of different soils, surroundings, and climate conditions (Tinti et al., 2018; Pinto et al., 2016).

The lignin content (49.32%) is above that reported by Zau et al. (2014) (i.e., 34.29%). According to Narciso et al. (2021), higher lignin values can enhance fiber connectivity, thereby improving the physical and mechanical properties of the panels. Lignin exhibits greater thermal stability and is more resistant to decomposition than cellulose or hemicellulose (TAPPI, 1997; Pereira et al., 2013).

The cellulose content was measured at 41.11%, slightly lower than the value reported by Zau et al. (2014) (i.e., 46.80%). Cellulose contributes to reducing the brittleness of lignocellulosic materials [37], leading to improved mechanical properties (Yan; Ksal; Huang, 2016; Sari et al., 2014).

The thermogravimetric analysis results are presented in Figure 1, illustrating distinct stages of mass loss. The first stage occurs between 26 °C and 105 °C, resulting in a 12.18٪ mass loss (with a maximum mass loss rate of 0.25 wt.٪/°C at 55.56 °C), with is likely due to moisture evaporation (El-Sayed; Khass; Mostafa, 2024; Ounas et al., 2011).

The second stage of mass loss starts at 178°C, corresponding to the decomposition of hemicellulose (Rebelo et al., 2019). According to Vamvuka et al. (2003), hemicellulose decomposes between 160 °C and 360 °C, while cellulose decomposes between 240°C and 390 °C. Yang et al. (2007) state that due to lignin’s aromatic ring structure with branches, degradation occurs at higher temperatures (up to 900 °C).

The DTG peak at 349.00 °C in Figure 1 corresponds to the maximum mass loss of cellulose (Chen et al., 2019), with a mass loss rate of 0.73wt.%/ºC.

It is possible to identify that the waste studied in this research can be used in thermoforming processes at temperatures above 200 °C without suffering degradation of its lignocellulosic components. It reinforces its potential use in producing panels that are alternative to those used in the MDP and MDF industries.

Physical characterization of panels

Figure 2 presents the results of the tests conducted on the panels with different resin percentages to determine the following physical properties: density, moisture content, and thickness swelling (TS). The Tukey test was applied to verify whether the means significantly differ. The yellow line in the graph represents the minimum value required by the NBR 14810 (ABNT, 2018) standard, while the dashed blue line represents the maximum value. The solid blue line corresponds to the maximum value required by the standard.

Physical and mechanical properties: (a) Density; (b) Moisture content; (c) Thickness swelling; e (d) Water Absorption

The increase in resin content to 25% and 35% did not affect the panel’s density. According to the NBR 14810-1 standard (ABNT, 2013), medium-density panels must be between 551 kg/m³ and 750 kg/m³; therefore, the composites produced were classified as high-density (Figure 2a). It can be inferred from the higher and lower density values of each panel in Figure 2a that there is good compaction and interaction between the particles, which can contribute to their strength in water absorption and improve their dimensional stability (Lopez et al., 2021). Furthermore, it was observed that the increase in the percentage of resin did not influence the density of the panels produced.

The values obtained for moisture content for the three panels range from 5.60% to 8.11%, falling within 5% and 13% (Figure 2b), as established by the NBR 14810-2 standard (ABNT, 2018). High moisture content can result in poorer mechanical properties and significant changes in other physical properties. As the resin has a hydrophobic characteristic, a higher percentage of resin can cover a greater percentage of wood particles, thus preventing the wood particles from absorbing a greater percentage of water, since these residues are hydrophilic (Fink, 2017; Murata et al., 1998).

Therefore, among the panels presented, the one produced with 25% resin is the most suitable for absorption by the panel production industries, as it meets the minimum physical requirements required by the NBR 14810 standard (ABNT, 2018) using the lowest amount of resin. However, although the panel produced with 35% resin had the lowest moisture content and thickness swelling compared with the panels produced with 25% and 30% resin, this option may lead to higher production costs.

Figure 2c shows the results of thickness swelling (TS) performed for 24 hours. The mean TS values ranged from 1.40% to 4.91% which showed significant differences for the panel with 25% resin. Exploring the underlying mechanisms responsible for the observed relationship between increased adhesive content and the reduction in moisture content and thickness swelling is essential. As the proportion of adhesive in the composite increases in the panel with 35% resin, a larger surface area of the wood particles becomes coated, which reduces their direct exposure to moisture. This adhesive coating effectively minimizes water absorption, subsequently limiting thickness swelling. Consequently, the dimensional stability of the panel is improved. A thorough understanding of this relationship is critical for optimizing sawdust panels’ mechanical properties and long-term durability (Cheng et al., 2016; Sunardi et al., 2019).

Concerning water absorption (WA), the value obtained for the panel produced with 25% resin was 28.62%, whereas for the panel with 30% resin, WA was equal to 4.84%. Finally, for the panel with 35% resin, WA was equal to 4.81% (Figure 2d). It can be inferred that higher levels of resin result in lower water absorption (Nejeliski et al., 2020). Seibel, Zimmer and Fiorio (2021) noted that increasing PU resin content reduces TS and WA properties, improving dimensional stability.

Figure 3 shows the SEM images of the panels’ surfaces. It can be noticed that the panel produced with 25% resin has a higher thickness swelling and water absorption content than the panels produced with 30% and 25% resin. However, they still comply with the NBR 14810 standard (ABNT, 2018). Figures 3b and 3c show images of samples with 30% and 35% resin, respectively.

Filler failures were observed in the panels, likely caused by natural waxes and extractives accumulated on the wood surfaces, which reduce resin/wood adhesion (Nejeliski; Duarte, 2020; Seibel; Zimmer; Fiorio, 2021), as well as by manufacturing parameters such as pressure, pressing time or temperature (Vamvuka et al., 2003; Khedari et al., 2004; Geethamma et al., 1998).

Mechanical characterization of panels

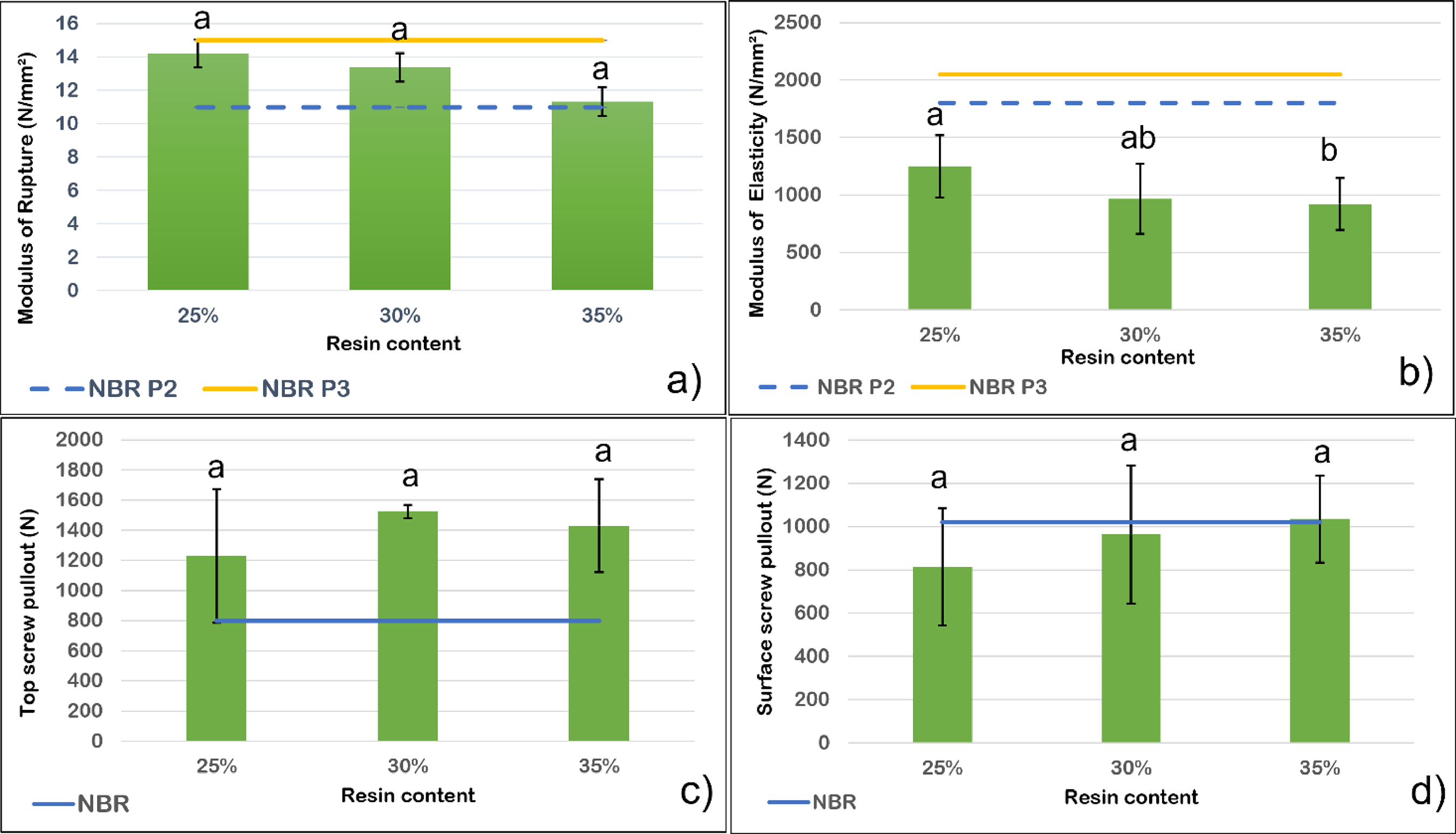

Figure 4 shows the following mechanical properties of the panels:

Mechanical properties: (a) Modulus of rupture (MOR); (b) modulus of elasticity (MOE); (c) top screw pullout (TSP); e (d) surface screw pullout (SSP)

-

modulus of rupture (MOR), Figure 4a;

-

modulus of elasticity (MOE), Figure 4b;

-

top screw pullout (TSP), Figure 4c; and

-

surface screw pullout (SSP), Figure 4d.

The NBR 14810-2 standard (ABNT, 2018) establishes a minimum MOR value of 11 N/mm² for non-structural panels intended for indoor use in dry conditions (type P2) and a minimum MOR value of 15 N/mm² for non-structural panels intended for use in humid conditions (type P3) (Figure 4a).

When evaluating the effects of the combination of wood sawdust on the mechanical behavior of particleboards using polyurethane/epoxy/polyvinyl acetate resins, Sunardi et al. (2019) obtained MOR values ranging from 11.41 N/mm² to 16.38 N/mm², which are similar to those obtained in this study, which were as follows:

-

14.20 N/mm² for panel with 25% resin;

-

13.36 N/mm² for panel with 30% resin; e

-

11.32 N/mm² for panel with 35% resin.

They highlighted that the contact between the surface of the filler material and the matrix is the cause of the composite’s strong bond.

Concerning the maximum value, Iwakiri et al. (2016) obtained MOR values ranging from 12 N/mm² to 16 N/mm² when evaluating the wood mixture quality of six wood species from the Amazon and Pinus Taeda, with urea-formaldehyde as the binder. Zau et al. (2014), using wood residues from the Amazon with castor oil-based polyurethane resin, achieved results ranging from 14.3 N/mm² to 28.3 N/mm², which are high values compared with those found in this work. Although they observed that the increase in the amount of resin influences the MOR, this was not observed in the present study.

The results of the modulus of elasticity (MOE), shown in Figure 4b, do not comply with the NBR 14810-2 standard (ABNT, 2018), which sets the minimum value of 1800 N/mm² for type P2 panels and 2050 N/mm² for type P3 panels. The modulus of elasticity (MOE) is a fundamental metric for evaluating the rigidity of panels, determining the material’s capacity for elastic deformation before permanent plastic deformation occurs, as described in NBR 14810 (ABNT, 2018). A critical observation when analyzing the influence of resin content on MOE is that an increase in resin content tends to reduce the panels’ flexibility. This trend can be attributed to the nature of the resin used, which becomes significantly more rigid after the polymer crosslinking process.

Previous studies support this analysis. For example, Zau et al. (2014) produced panels reinforced with cumaru wood residues, using a 40-mesh particle size and varying the content of polyurethane resin derived from castor oil (10%, 12.5%, and 15%). The results indicated that panels with lower wood residue content exhibited reduced MOE values, highlighting the correlation between resin concentration and panel rigidity. The MOE values obtained in this study were lower than the values obtained by composites produced with 8% urea-formaldehyde resin reinforced with tropical wood reported in the works by Iwakiri et al. (2016) (ranging from 1814 N/mm² to 2305 N/mm²) and Zau et al. (2014) (ranging from 1933 N/mm² to 2987 N/mm²), who produced panels with cumaru wood residue bonded with 10%, 12.5% and 15% polyurethane resin derived from castor oil. Furthermore, these lower MOE values compared to the recommended values of NBR 14810-1 (ABNT, 2013) standard may have been caused by a lower cellulose content, as cellulose is responsible for the strength and stiffness of fibers (Wool; Sun, 2011).

Figure 4c presents the results of the screw pullout strength tests. According to the NBR 14810-2 standard (ABNT, 2002), the minimum value required for top screw pullout is 800 N, and the lowest value obtained was 1229.45 N, corresponding to the panel with 25% resin (Figure 4c). In addition, the statistical analysis of the top screw pullout means for the three types of panels did not show significant differences, as well as for the modulus of rupture (MOR). However, a significant difference was observed in the modulus of elasticity (MOE), in which the panel produced with 25% resin performed better, while the performance of the panels produced with 30% and 35% resin remained unchanged.

Regarding the surface screw pullout test, only the panel with 35% resin reached a value above the minimum specified in the NBR 14810 standard (ABNT, 2002), which is 1020 N (Figure 4d). However, the ANSI A208.1 standard (ANSI, 1999) sets a minimum value of 900 N. In this case, the panel with 25% resin is the only one that does not meet this standard. According to Zau et al. (2014), higher amounts of resin result in higher SPF (Screw Pullout Face), as observed in this study.

Oliveira et al. (2016) evaluated three types of conventional panels for use in the furniture industry, i.e., pine, Eucalyptus, and sugarcane bagasse. They obtained lower values than those obtained in the present work:

-

TSP equal to 474.6N, 710N, and 520.7N; and

-

SSP equal to 438.36N, 831.6N, and 582.5N, respectively.

Conclusions

Particleboard panels of high density were produced using a mixture of sawdust from tropical woods sourced from the Brazilian Amazon rainforest. Increasing the polyurethane resin content improved thickness swelling and reduced water absorption of the panels. SEM images revealed lower porosity in the samples, contributing to decreased thickness swelling and water absorption. Regarding the modulus of rupture, the panels met the minimum value established in the NBR 14810-2 standard for non-structural panels intended for indoor use in dry (ABNT, 2018). However, modulus of elasticity (MOE) values did not meet standard requirements and were likely influenced by the cellulose and resin content. Therefore, future research should focus on strategies to enhance MOE’s values in these panels.

Screw pullout strength tests indicated performance variations with resin content, with higher resin levels leading to improved surface screw pullout values.

In summary, the study demonstrates the feasibility of utilizing sawdust from various wood species for panel production, highlighting the importance of resin content in influencing both physical and mechanical properties. Further optimization of resin levels could enhance panel performance, offering sustainable alternatives for industrial applications.

In the broader context, this research addresses a significant gap in the existing literature by exploring the potential of tropical wood residues, particularly from the Amazon, for sustainable panel production. The study underscores the crucial role of resin content in determining panel performance and suggests that further optimization could provide viable, eco-friendly alternatives for the civil construction and furniture industries. By advancing the understanding of how tropical wood residues can be effectively utilized, this work contributes to the development of innovative, sustainable materials that align with global efforts to promote responsible resource use and environmental stewardship.

References

- AMERICAN NATIONAL STANDARDS INSTITUTE. A208.1: particleboards physical & mechanical properties requirements. New York, 1999.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 14810: painéis de partículas de média densidade: parte 2: Requisitos e métodos de ensaio. Rio de Janeiro, 2018.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 14810-1: painéis de partículas de média densidade: terminologia. Rio de Janeiro, 2013.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 14810-2: painéis de partículas de média densidade: terminologia. Rio de Janeiro, 2002.

- BEECH, E. et al. GlobalTreeSearch: the first complete global database of tree species and country distributions. Journal of Sustainable Forestry, v. 36, n. 5, p. 454-489, 2017.

- BERTOLINI, M. S. et al. Eco-panels based on wastes from urban trees and castor oil Polyurethane resin. International Journal of Agriculture and Forestry, v. 3, n. 1, p. 12-15, 2013.

- CÉSAR, A. A. D. S. et al. Transformation of rice husk into a product with higher added value: Potential for the production of particulate panels. Ciencia Florestal, v. 27, n. 1, p. 303-313, 2017.

- CHEN, W. H. et al. Torrefaction, pyrolysis and two-stage thermodegradation of hemicellulose, cellulose and lignina. Fuel, v. 258, p. 116168, 2019.

- CHENG, X. et al. Effect of the particle geometry and adhesive mass percentage on the physical and mechanical properties of particleboard made from peanut hull. BioResources, v. 11, n. 3, p. 7271-7281, 2016.

- DE SOUZA, J. T. et al. Non-destructive properties of MDP produced with wood particles and Ilex paraguariensis. Scientia Forestalis/Forest Sciences, v. 46, n. 119, p. 507-518, 2018.

- DE SOUZA, M. V. et al. Particleboards manufactured from Tectona grandis wood waste with homogeneous and three-layer heterogeneous compositions for commercial purposes. BioResources, v. 17, n. 3, p. 5011, 2022.

- DEDAVID, B. A.; GOMES, C. I.; MACHADO, G. Microscopia eletrônica de varredura: aplicações e preparação de amostras: materiais poliméricos, metálicos e semicondutores. Porto Alegre: EdiPUCRS, 2007.

- DIAS, F. M. Aplicação de adesivo poliuretano à base de mamona na fabricação de painéis de madeira compensada e aglomerada São Carlos, 2005. Tese (Doutorado em Ciência e Engenharia de Materiais) - Universidade de São Paulo, São Carlos, 2005.

- DOS SANTOS, G. M. et al. Does the moisture content of mercerized wood influence the modulus of rupture of thermopressed polyurethane-based composites? Industrial Crops and Products, v. 206, p. 117585, 2023.

- ELGINOZ, N. et al. Wood waste recycling in Sweden: industrial, environmental, social, and economic challenges and benefits. Sustainability, v. 16, n. 14, p. 5933, 2024.

- EL-SAYED, S. A.; KHASS, T. M.; MOSTAFA, M. E. Thermal degradation behaviour and chemical kinetic characteristics of biomass pyrolysis using TG/DTG/DTA techniques. Biomass Conversion and Biorefinery, v. 14, n. 15, p. 17779-17803, 2024.

- EUROPEAN COMMITTEE FOR STANDARDIZATION. EN 312: particleboard: specifications. Brussels, 2003.

- FAN, X.; NAGARAJ, V. In-situ moisture desorption characterization of epoxy mold compound. In: INTERNATIONAL THERMAL, MECHANICAL AND MULTI-PHYSICS SIMULATION AND EXPERIMENTS IN MICROELECTRONICS AND MICROSYSTEMS, 13., 2012. Proceedings […] 2012.

- FARIA, D. L. et al. Particleboards produced with different proportions of Hevea brasiliensis: Residual wood valorization in higher value added products. Ciência e Agrotecnologia, v. 45, 2021.

- FINK, J. K. Reactive polymers: fundamentals and applications: a concise guide to industrial polymers. New York: William Andrew, 2017.

- GEETHAMMA, V. G. et al. Composite of short coir fibres and natural rubber: effect of chemical modification, loading and orientation of fibre. Polymer, v. 39, n. 6-7, p. 1483-1491, 1998.

- INOCENTE, J. M. et al. Study for vitreous waste recovery in the formulation of heavy clay ceramics. Material Science & Engineering International Journal, v. 1, n. 2, p. 56-60, 2017.

-

INTERNATIONAL TROPICAL TIMBER ORGANIZATION. Biennial review and assessment. 2019. Available: http://www.itto.int/news_releases/id=5195 Access: 20 mar. 2024.

» http://www.itto.int/news_releases/id=5195 - IWAKIRI, S. et al. Production of agglomerated panels with mixtures of six species of wood from the Amazon and Pinus taeda. Floresta, v. 46, n. 2, p. 259-267, 2016.

- KHEDARI, J. et al. New low-cost insulation particleboards from mixture of durian peel and coconut coir. Building and Environment, v. 39, n. 1, p. 59-65, 2004.

- LEÃO, M. A. Fibras de licuri: um reforço alternativo de compósitos poliméricos. Natal, 2008. Dissertação (Mestrado em Engenharia de Materiais) - Universidade Federal do Rio Grande do Norte, Natal, 2008.

- LIRA, J. O. B.; SILVA, K. C. G.; ANDERSEN, S. L. F. Estudo das características de combustão de resíduos sólidos da região nordeste utilizando análise termogravimétrica. In: CONGRESSO BRASILEIRO DE ENGENHARIA QUÍMICA, 20., Florianópolis, 2014. Anais [...] Florianópolis, 2014.

- LOPEZ, Y. M. et al Relationship between internal bond properties and X-ray densitometry of wood plastic composite. Composites Part B: Engineering, v. 204, p. 108477, 2021.

- MEINLSCHMIDT, P.; MAURUSCHAT, D.; BRIESEMEISTER, R. Altholzsituation in Europa und Deutschland. Chemie Ingenieur Technik, v. 88, n. 4, p. 475–482, abr. 2016.

- MONTGOMERY, D. C. Design and analysis of experiments New York: John Wiley & Sons, 2017.

- MURATA, S. et al. Synthesis and hydrolysis resistance of polyurethane derived from 2, 4-diethyl-1, 5-pentanediol. Polymer Degradation and Stability, v. 61, n. 3, p. 527-534, 1998.

- NARCISO, C. R. P. et al. Potential for the use of coconut husk in the production of medium density particleboard. Waste and Biomass Valorization, v. 12, n. 3, p. 1647–1658, 2021.

- NEJELISKI, D. M.; DUARTE, L. D. C. Waterproofing of bottle gourd (Lagenaria siceraria) with castor oil polyurethane resin. Matéria, Rio de Janeiro, v. 25, n. 3, 2020.

- NOGUEIRA, I. M. dos S.; LAHR, F. A. R.; GIACON, V. M. Desenvolvimento e caracterização de painéis de partículas aglomeradas utilizando o resíduo do ouriço da Castanha-do-Brasil (Bertholletia excelsa) e resina poliuretana derivada do óleo da mamona. Matéria, Rio de Janeiro, v. 23, n. 1, p. e-11985, 2018.

- OLIVEIRA, S. L. et al Particleboard panels made from sugarcane bagasse: characterization for use in the furniture industry. Materials Research, v. 19, n. 4, p. 914-922, 2016.

- OUNAS, A. et al. Pyrolysis of olive residue and sugar cane bagasse: non-isothermal thermogravimetric kinetic analysis. Bioresource Technology, v. 102, n. 24, p. 11234-11238, 2011.

- PEDZIK, M.; JANISZEWSKA, D.; ROGOZIŃSKI, T. Alternative lignocellulosic raw materials in particleboard production: a review. Industrial Crops and Products, v. 174, 2021.

- PEREIRA, B. L. C. et al. Estudo da degradação térmica da madeira de Eucalyptus através de termogravimetria e calorimetria. Revista Árvore, v. 37, p. 567-576, 2013.

- PINTO, E. M. et al Thermal degradation and charring rate of and wood species. The Open Construction & Building Technology Journal, v. 10, n. 1, 2016.

- POLETTO, M.; ORNAGHI JÚNIOR, H. L.; ZATTERA, A. J. Native cellulose: structure, characterization and thermal properties. Materials, v. 7, n. 9, p. 6105–6119, 2014.

- RAMOS, W. F. et al. Analysis of the timber industry in the Amazon: Management, use and storage of waste. Revista Brasileira de Ciências Ambientais, v. 43, p. 1–16, 2017.

- REBELO, V. et al. Effects of mercerization in the chemical and morphological properties of amazon piassava. Polímeros, v. 29, n. 1, p. 2–7, 2019.

- SARI, B. et al Effects of chemical composition of wood and resin type on properties of particleboard. Lignocellulose Journal, v. 1, p. 174-184, 2014.

- SEIBEL, R. K.; ZIMMER, A.; FIORIO, R. Development and characterization of novel castor oil-based polyurethane composites containing wood sawdust and rubber tire powder. Polymers and Polymer Composites, v. 29, n. 7, p.876-887, 2021.

- SILVA, J. V. F. et al. Characterization of particleboards produced with Pinus spp. waste. Scientia Forestalis, v. 111, p. 623-628, 2016.

- SUGAHARA, E. et al Comparative study of plywood boards produced with castor oil-based polyurethane and phenol-formaldehyde using Pinus Taeda l. veneers treated with chromated copper arsenate. Forests, v. 13, n. 7, p. 1144, 2022.

- SUGAHARA, E. S. et al. High-density particleboard made from agro-industrial waste and different adhesives. BioResources, v. 14, n. 3, p. 5162-5170, 2019.

- SUNARDI, M. F. et al. The Effect of wood sawdust mesh combination on mechanical behaviour of particle board. IOP Conference Series: Materials Science and Engineering, v. 494, n. 1, 2019.

- SURDI, P. G. et al. Particleboard production with residues from mechanical processing of Amazonian woods. Revista Árvore, v. 43, e430102, 2019.

- TECHNICAL ASSOCIATION FOR THE PULP, PAPER AND CONVERTING INDUSTRY. T211 om-02: ash in wood, pulp, paper and paperboard: combustion at 525ºC. Atlanta, 2002a.

- TECHNICAL ASSOCIATION FOR THE PULP, PAPER AND CONVERTING INDUSTRY. T222 om-02: acid-insoluble lignin in wood and pulp. Atlanta, 2002b.

- TECHNICAL ASSOCIATION FOR THE PULP, PAPER AND CONVERTING INDUSTRY. T204 cm-97: solvent extractives of wood and pulp. Atlanta, 1997.

- TINTI, V. P. et al. Propiedades físicas y densitometría de rayos X en tableros de residuos de madera. Revista Ciência da Madeira, v. 9, n. 2, 2018.

- VAMVUKA, D. et al. Pyrolysis characteristics and kinetics of biomass residuals mixtures with lignite? Fuel, v. 82, n. 15-17, p. 1949-1960, 2003.

- WOOL, R.; SUN, X. S. Bio-based polymers and composites London: Elsevier, 2011.

- YAN, L.; KASAL, B.; HUANG, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Composites Part B: Engineering, v. 92, p. 94-132, 2016.

- YANG, H. et al. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel, v. 86, n. 12-13, p. 1781-1788, 2007.

- ZAU, M. D. L. et al Chemical, physical and mechanical properties of particleboard produced with amazon wood waste - Cumaru (Dipteryx Odorata) - and castor oil based polyurethane adhesive. Polímeros, v. 24, n. 6, p. 726-732, 2014.

Edited by

-

Editores:

Marcelo Henrique Farias de Medeiros e Julio Cesar Molina

Publication Dates

-

Publication in this collection

17 Mar 2025 -

Date of issue

Jan-Dec 2025

History

-

Received

16 June 2024 -

Accepted

03 Sept 2024

Wood sawdust residues from the Amazon: a sustainable alternative for panel production

Wood sawdust residues from the Amazon: a sustainable alternative for panel production