Abstract

This paper examines the impacts of the total replacement of Natural Coarse Aggregates (NCA) by Recycled Concrete Coarse Aggregates (RCA) on the mechanical properties in concrete's fresh and hardened state. It also investigates the impact of RCA on the response and resistance of slab-column connections with and without shear reinforcement. The total replacement of NCA by RCA reduced by 21.8% and 37.1% the compressive and tensile strength of concrete for the concrete mix investigation. Variations in mechanical properties were observed in the concrete used for slab-column connections, but due to material heterogeneity, they could not solely be attributed to the use of RCA. Using concrete with 100% RCA reduced in 5.6% and 12.6% the punching strength of slabs without and with shear reinforcement. The load-displacement response and the cracking pattern of the slab-column connections were not affected by the use of 100% RCA.

Keywords

Recycled concrete aggregate; Mechanical properties; Flat slab; Punching shear

Resumo

Este artigo examina os impactos da substituição total de Agregados Graúdos Naturais (AGN) por Agregados Graúdos Reciclados de Concreto (ARCO) nas propriedades mecânicas do concreto no estado fresco e endurecido. Também investiga o impacto do ARCO na resposta e resistência de ligações laje-pilar com e sem armadura de cisalhamento. A substituição total do AGN pelo ARCO reduziu em 21,8% e 37,1% a resistência à compressão e tração do concreto no estudo da mistura de concreto. Variações nas propriedades mecânicas foram observadas no concreto utilizado nas ligações laje-pilar, mas devido à heterogeneidade do material, não puderam ser atribuídas apenas ao uso do ARCO. A utilização de concreto com 100% de ARCO reduziu em 5,6% e 12,6% a resistência à punção de lajes sem e com armadura de cisalhamento. A resposta carga-deslocamento e o padrão de fissuração das ligações laje-pilar não foram afetados pela utilização de 100% ARCO.

Palavras-chave

Agregado reciclado de concreto; Propriedades mecânicas; Laje lisa; Punção

Introduction

The consumption of natural resources by the construction industry is increasing, driven by the development of large-scale projects necessary for the expansion of urban centers, which contributes to the rise in waste generation. Sasanipour and Aslani (2020) emphasize the global concern for environmental protection, highlighting that solutions involve, among many aspects, the management of Construction and Demolition Waste (CDW). In this context, it is necessary to seek alternatives to the use of non-renewable materials that cause degradation in riverbeds and rocky sources. Additionally, proper management and handling of CDW resulting from these activities should be carried out (Bhat, 2021). According to Plaza et al. (2021), recycling and reusing concrete waste is an alternative that would extend the life cycle of non-renewable materials, since concrete is the primary constituent of CDW (Soares et al., 2014).

In the face of this scenario, the construction industry, which historically followed the linear economy of "take-make-dispose," is undergoing a significant transformation by adopting the circular economy, reintegrating waste into the production cycle (Illankoon; Vithanage, 2023; Benachio; Freitas; Tavares, 2020; Blomsma et al., 2023). Thus, the selection of concrete waste and its transformation into Recycled Concrete Coarse Aggregate (RCA) is a possibility for reintegrating this waste into the construction industry's production chain. Its use also contributes to reducing environmental damage since between 40% to 50% of the total volume of a concrete mix consists of Coarse Aggregate (CA) (Gholambour; Ozbakkaloglu, 2018). Consequently, the technical feasibility of using RCA in new cementitious matrices has been studied by various researchers such as Santos and Leite (2018), Figueiredo et al. (2020), Tam et al.(2021), Tam, Soomro and Evangelista (2021), Salles et al. (2021), and Aragoncillo et al. (2023). These authors extensively investigated the mechanical properties of concrete with the replacement of Natural Coarse Aggregate (NCA) by RCA, developing methods capable of improving the microstructural properties of recycled aggregate, the effects of residual mortar present in these aggregates, and adaptations in recycled concrete dosing methods.

RCA can be used in various applications, both structural and non-structural, but its use in structures is limited to 20% of the total aggregate weight in Brazil, according to NBR 15116 (ABNT, 2021a). Its use in structural concrete requires special attention due to its influence on the mechanical properties of concrete (Gómez-Soberón, 2002; Poon; Shui; Lam, 2004; Amorim; Brito; Evangelista, 2012; Kwan et al., 2012; Matias et al., 2013), as the heterogeneity of RCA can lead to variability in the properties of concrete with recycled aggregates. According to Sasanipour and Aslani (2020), the mechanical properties of concrete with RCA are affected by the mortar adhered to the surface of the aggregate, impacting porosity, resulting in increased water absorption and lower density of RCA. However, according to Muduli and Mukharjee (2020), these properties are improved when the strength of the original concrete is known, as concretes with higher strength exhibit lower porosity in the transition zone (TZ).

Regarding the compressive strength of concrete (fc), researchers report a reduction in strength with an increase in the water-cement (wc) ratio (Gómez-Soberón, 2002; Poon; Shui; Lam, 2004; Xiao; Zhang, 2005; Kou; Poon; Chan, 2008; Kwan et al., 2012; Evangelista; Brito, 2010; Guedes et al., 2013). However, Pepe (2015) emphasizes that this reduction may be influenced by the quality of RCA for concretes with 100% replacement of NCA by RCA. Pacheco et al. (2019) highlight that the decrease in the modulus of elasticity of concrete (Ec) is more evident, as Ec is influenced by the stiffness of the aggregates, while fc is affected by the characteristics of the cement paste. Additionally, Pacheco et al. (2019) state that the increase in intrinsic porosity from RCA incorporation leads to a decrease in material stiffness and, consequently, the modulus of elasticity. The tensile strength of concrete (fct) with RCA is also widely discussed in the scientific literature (Etxeberria; Mari; Vázquez, 2007; Malesev; Radonjanin; Marinkovic, 2010; Soares et al., 2014; Pacheco et al., 2019). However, the conclusions indicate little influence of RCA incorporation on the tensile strength (fct).

Authors such as Yang and Han (2006), Ignjatovic et al. (2013), Sadati et al. (2016), Seara-Paz et al. (2018), Sunayana and Barai (2018), and Cardoso et al. (2021) have studied the influence of recycled aggregates on the behavior of structural elements, such as beams and columns, examining their response when subjected to bending and shear. However, the structural performance of concrete produced with RCA still presents several uncertainties. One of the areas with fewer studies relates to the application of concrete with RCA in the production of reinforced concrete slabs, due to the high cost of this type of research as they are elements with large dimensions and volumes of concrete and steel.

In this scenario, the use of concrete with replacement of NCA by RCA to produce reinforced concrete flat slabs is of great technical and scientific interest, as the use of these aggregates has the potential to affect both the behavior in service (vertical displacements and crack opening) and punching shear resistance. Punching shear deserves special attention in the case of slabs with concretes with replacement of coarse aggregates, as aggregate interlock and the rotation of the slab-column connection are important parameters that can influence the resistance according to Classen and Kalaus (2023), among others.

Few studies are available in the literature regarding the punching shear resistance of reinforced concrete flat slabs with RCA concretes (Rao; Reddy; Ghorpade, 2012; Reis et al., 2015; Francesconi; Pani; Stochino, 2016; Mahmoud; Tony; Saeed, 2018; Sahoo; Singh, 2020, 2021). The cited works, besides presenting divergent conclusions on the influence of coarse aggregate replacement on punching shear resistance, also mostly refer to tests on small-scale specimens, with thicknesses ranging from 50 mm to 100 mm, which are not very representative of the reality of slab-column connections in building floors with flat slabs. Additionally, there are practically no studies investigating the punching shear resistance of slabs with RCA concretes and shear reinforcement. The only available work is that of Lou, Zong and Du (2014), but due to the small thickness of the slab, it is not possible to ensure adequate anchorage of the shear reinforcement.

This study aims to investigate the effects of replacing natural coarse aggregates with recycled concrete coarse aggregates on both their mechanical properties in the hardened state and the behavior and punching shear resistance of slab-column connections with and without shear reinforcement. Two groups of concrete were produced, one as a reference with only natural aggregates and the other with 100% replacement of natural coarse aggregates with recycled concrete coarse aggregates, in order to assess the maximum impact on concrete and slab performance. The effects of aggregate substitution on compressive strength, tensile strength, and concrete microstructure were analyzed. Subsequently, the concrete was used to produce slab-column connections with 0% and 100% RCA, testing two slabs without shear reinforcement and two slabs with double-headed studs. The structural behavior of the slabs is discussed in terms of their vertical displacements, and comparisons are made regarding the experimentally measured ultimate punching shear resistance.

This work has been divided into four stages: the first stage includes an introduction that contextualizes the problem analyzed; the second stage focuses on the study of the mechanical properties of concrete with RCA and NCA, presenting the methods and results of a preliminary study of the mix proportions; the third stage discusses the application of the proposed mix in flat slabs, both with and without shear reinforcement, evaluating the punching shear resistance in slab-column connections and detailing the methods and results of the application; and finally, the fourth stage concludes the paper by summarizing the main scientific contributions achieved through this study.

Investigations of mechanical properties of the concrete with RCA and NCA

This section presents an initial analysis of the proposed mix, investigating the effect of replacing NCA with RCA on the mechanical properties of the concrete. Although NBR 15116 (ABNT, 2021a) limits structural use to 20% replacement, a reference concrete and another with 100% recycled aggregate replacement were used to assess the maximum reduction in strength. The natural and recycled aggregates were characterized and the w/c ratio was adjusted to 100% replacement to maintain workability. The mechanical tests carried out were compressive test, splitting test and flexural tensile test. In addition, a microstructural check of the concrete was carried out to better understand the effects and zones of fragility.

Characterization of the materials

The cement used was CPV-ARI-RS, the fine aggregate used originated from quartz, and the natural coarse aggregate used was basaltic gravel No. 1 (19 mm). The RCA used originated from the processing of cylindrical test specimens from the discard of concrete technology control companies. In this stage, test specimens with known compressive strength ranging from 25 to 35 MPa and with gravel as natural coarse aggregate were used.

For this research, the material was crushed and sieved, with a defined particle size distribution between pass-throughs on slotted sieve 19-mm-sieve and retained on slotted 4.8-mm-sieve. The results obtained with the particle size distribution and the density of natural and recycled aggregates are presented in Table 1. It is possible to observe the difference in densities of the coarse aggregates, with a decrease in that of the RCA compared to the NCA, as well as the higher presence of powdery materials in the composition of the RCA, combined with a higher moisture content compared to the NCA. These factors directly influence the behavior of concrete in both the fresh and hardened states.

Concrete dosage

Table 2 presents the concrete mixtures of the reference concrete and the recycled concrete. Two distinct mixtures were prepared: CC with 100% NCA and RAC with 100% RCA; the mix proportions were made in weight. The mixtures produced had the same mortar content, 51%, aiming for the same fc28 of 25 MPa at 28 days. The workability of the concrete mixtures was evaluated through slump tests following NBR 16889 (ABNT, 2020), and C143/C143M-12 (ASTM, 2015a), and the measured values ranged from 100 ± 20 mm for both mixtures.

These mix proportions were an initial study for the concrete that would be used to pour the slab-column connections, which test results are presented in Section 3. In this stage, maintaining the workability of concrete was essential to ensure proper concrete compaction due to the large volume of concrete and high amount of flexural and shear rebars. The measured reduction in the mechanical properties of concrete was considered acceptable, as the concrete remained within the limits for structural concrete design.

Mechanical properties

The concrete compressive strength is measured using three cylinders specimens with the dimensions of 100x200 mm (ABNT, 2018; ASTM, 2023c). The splitting tensile strength test was performed on the three cylindrical specimens with the dimensions of 100x200 mm (ABNT, 2011b; ASTM, 2017). The flexural strength test was performed on the three beams shaped specimens with the dimensions of 100x100x400 mm (ABNT, 2010; ASTM, 2010). All tests were performed at 28 days after pouring. Considering the replacement of natural aggregate by recycled aggregate, a reduction in compressive strength and splitting tensile strength was observed, 21.8% and 37.1%, respectively. Regarding flexural tensile strength, similar strengths were observed between CC and RAC, as shown in Table 3.

Authors such as Padhi et al. (2018), Ditz and Amaro (2019), Gholampour and Ozbakkaloglu (2020); also found a decrease in the strength of concrete with RCA. These results are related to the greater porosity of this aggregate, noticeable in the decrease in the specific mass of RCA, which occurs due to the mortar of the original concrete adhering to the recycled aggregate; and with the higher water/cement ratio used to maintain adequate workability. In addition, Bhat (2021) relates this reduction to the occurrence of weaker transition zones and the presence of microcracks in the recycled aggregate, caused by the crushing process.

After carrying out the property characterization tests, it was observed that with the 11.8% increase in the w/c ratio between the CC concrete and the RAC concrete, justified by maintaining the workability of the material, there was a 21.8% reduction in the concrete's compressive strength. After this study of the dosage, it was decided to maintain this increase in the w/c ratio for the mix that was adopted in the production of the slabs, since the compressive strength of the concrete still met the code specifications of NBR 6118 (ABNT, 2023) for structural concrete, which defines an fcm greater than 20 MPa, so there was no need to change the mix with the use of additives.

Microstructural Analysis by Scanning Electron Microscopy with energy-dispersive spectroscopy

To enrich the analyses and enhance the understanding of the effects caused by RCA, a microstructure examination of the material was carried out by scanning electron microscopy (SEM) analysis with energy-dispersive spectroscopy (EDS). The samples for SEM analysis with EDS were selected after the test specimens were crushed. The water absorbed by the samples during the curing process was removed by drying them in an oven at 100 °C for 10 minutes. The SEM with EDS analyses were carried out using the gold metallization process. Fractured samples were used to visualize the morphological characteristics and heterogeneity between the original concrete and the new concrete. The equipment used was a ZEISS SEM model LEO-1430 with EDS IXRF model Sirius-SD attached, the preparation conditions were: electron beam current = 100 µA, constant acceleration voltage = 20 kV, working distance 15 mm.

In Figure 1, a higher quantity of pores in the concrete with 100% recycled aggregate can be identified. This occurs due to the presence of the former adhered mortar, rendering the aggregate more porous and increasing water absorption.

Using the images obtained through SEM, in conjunction with Energy Dispersive Spectroscopy (EDS) graphs, it was possible to identify and distinguish the constituent components of the samples. Figure 2a shows the conventional concrete (CC), where at point 2, Si was identified in greater quantity than all other elements. Subsequently, a low concentration of Al and Mg, Fe, Ca, and K was observed, as shown in Figure 2b, characterizing the Natural Concrete Aggregate (NCA) used in the sample.

Figure 3a shows the RAC, where at point 1, large quantities of Si were identified, as shown in Figure 3b, characterizing an RCA. At point 3, a much larger portion of Ca was detected in relation to Si and Al, as shown in Figure 3c, indicating that this is a point of cement paste.

With the SEM results analyzed along with the mechanical results, it is possible to notice the greater fragility of RCA compared to NCA, inducing failure in RCA due to microcracking that occurs in the former mortar adhered to the aggregate caused during the processing, as illustrated in Figure 4, leading to reductions in the mechanical strength of concrete. Bhat (2021) relates the possible reduction in mechanical properties to the occurrence of weaker transition zones and the presence of microcracks in the recycled aggregate caused by the crushing process.

Applications in slab-column connections: punching shear resistance

This section presents the results of the impact of 100% RCA replacement on the response and punching shear strength of slab-column connections. Four flat slabs were tested: two without shear reinforcement, one with NCA (S-1.2-0) and another with 100% of RCA (S-1.2-100); and two with double-headed studs as punching shear reinforcement, one with NCA (SS-1.2-0) and another with RCA (SS-1.2-100). The compressive, tensile strength and modulus of elasticity of concrete were measured through tests on cylinder concrete samples.

Material used in the slabs

Considering the properties in the fresh state, workability was verified through the slump test, with results obtained in the range of 100 ± 20 mm for all slabs, lower slump values than those obtained in the design study, but still meeting the requirements specified in NBR 8953 (ABNT, 2015) and C143/C143M-12 (ASTM, 2015a) for structural concrete. Thus, the adjustment of the w/c ratio based on the RCA content proved to be effective in ensuring good workability.

In relation to the control of properties in the hardened state of slabs, tests of compressive strength, tensile strength, and modulus of elasticity were performed on the same day of their respective slab, with detailed results in Table 4.

The compressive strength of all slabs remained in the range of 20 to 25 MPa, complying with the requirements for use in structural concrete. According to Tam, Soomro and Evangelista (2021) and Li, Li and Cheng (2024), this variation in results, which was also observed in the first stage of this study, is dependent on the original concrete material and the properties of the adhered mortar.

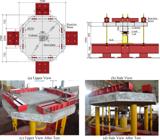

Slabs characteristics

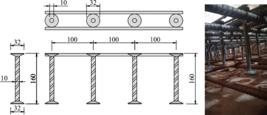

The slabs had an octagonal shape with distances between opposite sides of 2500 mm and a thickness of 210 mm. The slabs were subjected to an upward central loading through a central column measuring 300 mm on side and height. The loading pattern ensured that all slabs were tested with distributed supports arranged circumferentially at equidistant points using a loading radius of 1125 mm. Figure 5 shows the geometry of the tested slabs.

The tests investigated the maximum strength of four slabs, two without shear reinforcement and two with the shear reinforcement, with replacement rates of 0% and 100% of RCA. The flexural reinforcement ratio was 1.2%, and the shear reinforcement ratio using connectors was 0.34%.

Table 5 summarizes the characteristics of the tested slabs, with the RCA content (% RCA), the actual effective depth of the slabs measured in situ (d), flexural reinforcement ratio (ρ), bar diameter (øf), yield strength (fys), and modulus of elasticity (Es) of the flexural reinforcement.

The flexural reinforcement consisted of a mesh of straight CA-50 deformed steel bars symmetrically arranged in orthogonal directions on the upper and lower faces of the slabs. The anchorage of all flexural bars was done through 'U' type hooks. The hooks are positioned to encompass the upper bars and others the lower bars to prevent possible delamination failure. For slabs without shear reinforcement, 25 mm bars spaced at 250 mm and cover of 30 mm were used. For slabs with shear reinforcement, 16.0 mm bars with predominantly 100 mm spacing and cover of 30 mm with small variations due to the construction process were used. The shear reinforcement ratio was 0.34%. In all slabs, the bottom reinforcement consisted of 10.0 mm bars, with the same spacing as the top reinforcement, aiming to prevent slab cracking during their mobilization. The details can be observed in Figure 6. The design and detailing of the reinforcement of all slabs followed the criteria of NBR 6118 (ABNT, 2023).

For SS slabs, layers of shear reinforcement were positioned close to the support to ensure that failure occurred outside the region of the shear reinforcement. Figure 7 presents the detailing of the shear reinforcement for the studied slabs. The shear reinforcement used in SS slabs was steel connectors like double headed studs. All connectors were industrially produced with their shanks of CA50 deformed bars and their heads produced by melting the bar ends and welded to the support bars. Table 6 details the specifications of the shear reinforcement used. It includes the shear reinforcement ratio (ρw), double headed stud diameter (øw), yield strength of shear reinforcement (fyws), modulus of elasticity of shear reinforcement (Ews), number of layers, number of lines, spacing between the face of the column and the first layer (S0), and spacing between layers (Sr) of the shear reinforcement. The shear reinforcement ratio was calculated based on Eurocode 2 (ECS, 2023).

Test system

The slabs were tested using: a self-supporting metallic reaction system with 3000 kN capacity; a hydraulic cylinder with 3000 kN capacity; a load cell with a 3000 kN capacity and an accuracy of 1 kN; an electric pump for system activation; four stiff metal beams to distribute the reaction; eight steel tie rods used for the reaction; and eight steel plates symmetrically distributed relative to the center of the slab, serving as reaction points, providing a loading radius of 1125 mm. Figure 8 shows the layout, section, and a 3D view, with the slab radius being 1250 mm and the loading application radius 1125 mm.

Monitoring

For vertical displacement monitoring, a Linear Variable Differential Transformer (LVDT) was installed at the center of the column to measure the maximum displacement during the tests, as shown in Figure 9. The LVDT was fixed to a metal profile, which was positioned on the reaction beams of the testing system, causing them to move together, functioning as a yoke.

Results of vertical displacement and ultimate punching shear resistance

In Table 7, the vertical displacement and ultimate punching shear resistance results of the slab-column connection models are detailed. It is observed that the S-1.2-100 slab experiences a 5.6% loss in ultimate load, along with a 27.4% reduction in displacement prior to failure compared to the reference slab S-1.2-0. Furthermore, it was found that in the SS-1.2-100 slab there were decreases of 13% in the ultimate punching shear resistance and 24.6% in displacement prior to failure when compared to the SS-1.2-0 slab.

Furthermore, Figures 10a and 10b present the Load x Displacement behaviors of slabs without shear reinforcement and with Double Headed Studs, respectively, serving as a reference to evaluate the stiffness of the slabs and the influence of RCA on their behavior. In this regard, in this sense, rigid behavior was observed up to 200 kN for slabs S-1.2-0 and S-1.2-100, and up to 300 kN for slabs SS-1.2-0 and SS-1.2-100.

There was no effect on stiffness in the pre-crack load stage of the slab, with the curves matching, as observed in the tests of Sahoo and Singh (20-21). However, after the first crack, the slabs without shear reinforcement showed a change in stiffness and stopped overlapping. Unlike the slabs without shear reinforcement, the slabs reinforced with double-headed studs regain the same stiffness after both slabs crack.

Slabs without shear reinforcement were not significantly affected in terms of their resistance capacity, in line with Reis et al. (2015) and Francesconi, Pani and Stochino (2016). However, in the case of slabs with double-headed studs, the maximum resistance was influenced by the premature cracking of the slab with recycled aggregate that influence both the anchorage strength of the studs and the contribution of the concrete on slab strength.

In Figure 11, it is possible to verify the increase in load resulting from the use of shear reinforcement. The increase in punching shear resistance was 68% for slabs with natural aggregates and 54% for slabs with recycled concrete aggregates.

Results of cracking pattern and failure mode

The crack opening was monitored using a crack gauge. The monitored cracks were adjacent to the face of the column, one radial and one circumferential. It was observed that the cracks exhibited gradual stability with increasing load, from beginning to failure. The cracking initiated at loads close to 200 kN, demonstrating a similar cracking pattern and failure mode for slabs S-1.2-0 and S-1.2-100. The cracking pattern on the upper surface of the slabs showed initial cracks, tangential and radial cracks, originating from the region of the column towards the edges, followed by the development of shear cracks, forming a circular pattern around the column, such as a cone surface, indicative of punching shear failure, as seen in Figure 12. Regarding the slabs with shear reinforcement, SS-1.2-0 and SS-1.2-100, the cracking pattern and failure mode occurred similarly to the models without shear reinforcement, with the only difference being the initial crack load, which was approximately 300 kN. Tangential cracks were more stabilized, and there was constant growth until the end of the test for both slabs with Double Headed Studs. The cracking pattern of the RCA slabs was similar to that observed for the NCA slabs.

Conclusions

This paper presents the key findings of a study that investigated the effects of replacing Natural Coarse Aggregates (NCA) with Coarse Recycled Concrete Aggregates (RCA) on concrete's mechanical properties and the behaviour and punching strengths of slab-column connections. The study's main conclusions are as follows:

-

in the investigation of the concrete mix, it was observed that using Recycled Concrete Aggregate (RCA) reduced the compressive strength and tensile strength of concrete by up to 21.8% and 37.1%, respectively. This reduction is justified by the increase in the proportion of water in the mixture, which was conducted to ensure the workability of the concrete;

-

variations in the mechanical properties of the concrete actually used in manufacturing the slab-column connections were also observed. However, these variations indicated potential increases or decreases in the hardened concrete's mechanical properties. Thus, these fluctuations do not point to adverse impacts of RCA on the concrete's mechanical properties;

-

the differences in the mechanical properties of concrete associated with using RCA observed in the concrete mix investigation and the manufacturing of the slab column are related to the heterogeneity of the raw material used to produce the recycled concrete aggregates;

-

using recycled concrete aggregates did not affect the slabs' load-displacement response. Furthermore, no significant differences were observed in the cracking pattern of the slabs associated with using RCA compared to the slabs with NCA, indicating the potential of using RCA in reinforced concrete flat slabs;

-

regardless of the aggregate type, all tested slabs presented punching shear failure. The punching shear strength was reduced by 5.6% and 12.6% due to the use of RCA in slabs without and with shear reinforcement, respectively; and

-

more experimental tests on full-scale slab-column connections are necessary to use RCA safely in flat slab buildings.

References

- AMERICAN SOCIETY FOR TESTING AND MATERIALS. C127/C127M-15: standard test method for relative density (specific gravity) and absorption of coarse aggregate. West Conshohocken, 2015b.

- AMERICAN SOCIETY FOR TESTING AND MATERIALS. C136/C136M-06: standard test method for sieve analysis of fine and coarse aggregates. West Conshohocken, 2015c.

- AMERICAN SOCIETY FOR TESTING AND MATERIALS. C143/C143M-12: standard test method for slump of hydraulic-cement concrete. West Conshohocken, 2015a.

- AMERICAN SOCIETY FOR TESTING AND MATERIALS. C29/C29M: standard test method for bulk density ("Unit Weight") and voids in aggregate. West Conshohocken, 2023a.

- AMERICAN SOCIETY FOR TESTING AND MATERIALS. C33/C33M-18: standard specification for concrete aggregates. West Conshohocken, 2023b.

- AMERICAN SOCIETY FOR TESTING AND MATERIALS. C39/C39M-21: standard test method for compressive strength of cylindrical concrete specimens: eLearning course. West Conshohocken, 2023c.

- AMERICAN SOCIETY FOR TESTING AND MATERIALS. C496-96: standard test method for splitting tensile strength of cylindrical concrete specimens. West Conshohocken, 2017.

- AMERICAN SOCIETY FOR TESTING AND MATERIALS. C566/C566M-19: standard test method for total evaporable moisture content of aggregate by drying. West Conshohocken, 2019.

- AMERICAN SOCIETY FOR TESTING AND MATERIALS. C78-09: standard test method for flexural strength of concrete (using simple beam with third-point loading). West Conshohocken, 2010.

- AMORIM, P.; BRITO, J. de; EVANGELISTA, L. Concrete made with coarse concrete aggregate: influence of curing on durability. ACI Materials Journal, v. 109, n. 2, p. 195-204, 2012.

- ARAGONCILLO, A. M. et al. Water sorptivity prediction model for concrete with all coarse recycled concrete aggregates. Construction and Building Materials, v. 394, p. 132128, 2023.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 12142: concreto: determinação da resistência à tração na flexão de corpos de prova prismáticos. Rio de Janeiro, 2010.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 15116: agregados reciclados para uso em argamassas e concretos de cimento Portland: requisitos e métodos de ensaio. Rio de Janeiro, 2021a.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 16889: concreto: determinação da consciência pelo abatimento do tronco de cone. Rio de Janeiro, 2020.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 16916: agregado miúdo: determinação da densidade e da absorção de água. Rio de Janeiro, 2021b.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 16972: agregados: determinação da massa unitária e do índice de vazios. Rio de Janeiro, 2021c.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 16973: agregados: determinação do material fino que passa pela peneira de 75 μm por lavagem. Rio de Janeiro, 2021d.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 5739: concreto: ensaio de compressão de corpos de prova cilíndricos. Rio de Janeiro, 2018.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 6118: projeto de estruturas de concreto. Rio de Janeiro, 2023.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7222: concreto e argamassa: determinação da resistência à tração por compressão diametral de corpos de prova cilíndricos. Rio de Janeiro, 2011b.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 8953: concreto para fins estruturais: classificação pela massa específica, por grupos de resistência e consistência. Rio de Janeiro, 2015.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 9939: agregado graúdo: determinação do teor de umidade total: método de ensaio. Rio de Janeiro, 2011a.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NM 248: agregados: determinação da composição granulométrica. Rio de Janeiro, 2001.

- BENACHIO, G. L. F.; FREITAS, M. C. D.; TAVARES, S. F. Circular economy in the construction industry: a systematic literature review. Journal of Cleaner Production, v. 260, 121046, 2020.

- BHAT, J. A. Effect of strength of parent concrete on the mechanical properties of recycled aggregate concrete. Materials Today: Proceedings, v. 42, p. 1462-1469, 2021.

- BLOMSMA, F. et al The ‘need for speed’: Towards circular disruption: what it is, how to make it happen and how to know it's happening. Business Strategy and the Environment, v. 32, p. 1010-1031, 2023.

- CARDOSO, A. C. et al. Influence of recycled concrete aggregates on the shear strength of reinforced concrete beams. Revista IBRACON de Estruturas e Materiais, v. 14, n. 1, e14109, 2021.

- CLASSEN, M.; KALUS, M. Punching Shear Response Theory (PSRT): a two degree of freedom kinematic theory for modeling the entire punching shear vs. Deformation response of RC slabs and footings. Engineering Structures, v. 291, n. 116197, 2023.

- DITZ, J. D.; AMARO, L. C. Análise das propriedades mecânicas do concreto de alta resistência com agregados de construção e demolição. Engenharia e Tecnologia, v. 11, n. 4, 2019.

- ETXEBERRIA, M.; MARI, A. R.; VÁZQUEZ, E. Recycled aggregate concrete as structural material. Materials and Structures, v. 40, p. 529–541, 2007.

- EUROPEAN COMMITTEE FOR STANDARDIZATION. Eurocode 2: design of concrete structures: part 1-1: general rules and rules for buildings, bridges and civil engineering structure. Brussels, 2023.

- EVANGELISTA, L.; BRITO, J. de. Durability performance of concrete made with fine recycled concrete aggregates. Cement and Concrete Composites, v. 32, n. 1, p. 9-14, 2010.

- FIGUEIREDO, P. O. et al.Influência dos métodos de britagem nas propriedades do agregado reciclado de concreto. Ambiente Construído, Porto Alegre, v. 20, n. 2, p. 99-111, abr./jun. 2020.

- FRANCESCONI, L.; PANI, L.; STOCHINO, F. Punching shear strength of reinforced recycled concrete slabs. Construction and Building Materials, v. 127, p. 248–263, 2016.

- GHOLAMPOIR, A.; OZBAKKALOGLU, T. A Review of natural fiber composites: properties, modification and processing techniques, characterization, applications. Journal of Materials Science, v. 55, p. 829-892. 2020.

- GHOLAMPOUR, A.; OZBAKKALOGLU, T. Time-dependent and long-term mechanical properties of concretes incorporating different grades of coarse recycled concrete aggregates. Engineering Structures, v. 157, p. 224-234, 2018.

- GÓMEZ-SOBERÓN, J. M. V. Creep of concrete with substitution of normal aggregate by recycled concrete aggregate. Material Science Engineering, v. 209, p. 461-474, 2002.

- GUEDES, M. et al. Microstructural characterization of concrete prepared with recycled aggregates. Microscopy and Microanalysis, v. 19, n. 5, p. 1222-1230, 2013.

- IGNJATOVIC, I. S. et al. Flexural behavior of reinforced recycled aggregate concrete beams under short-term loading. Materials and Structures, v. 46, p. 1045-1059, 2013.

- ILLANKOON, C.; VITHANAGE, S. C. Closing the loop in the construction industry: a systematic literature review on the development of circular economy. Journal of Building Engineering, v. 76, n. 107362, 2023.

- KOU, S. C.; POON, C. S.; CHAN, D. Influence of fly ash as a cement addition on the hardened properties of recycled aggregate concrete. Materials and Structures, v. 41, p. 1191-1201, 2008.

- KWAN, W. H. et al. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Construction and Building Materials, v. 26, n. 1, p. 565-573, 2012.

- LI, Z.; LI, L.; CHENG, S. Evaluation of modulus of elasticity of concrete containing both natural and recycled concrete aggregates. Journal of Cleaner Production, v. 447, 2024.

- LOU, J.; ZONG, Y.; DU, C. The failure mechanism and finite element analysis of recycled concrete two-way slabs with stud-shear reinforcement. Advanced Materials Research, v. 1020, p. 303-307, 2014.

- MAHMOUD, Z. I.; TONY, E. T. M.; SAEED, K. S. Punching shear behavior of recycled aggregate reinforced concrete slabs. Alexandria Engineering Journal, v. 57, p. 841–849, 2018.

- MALESEV, M.; RADONJANIN, V.; MARINKOVIC, S. Recycled concrete as aggregate for structural concrete production. Sustainability, v. 2, p. 1204-1225, 2010.

- MATIAS, D. et al. Mechanical properties of concrete produced with recycled coarse aggregates: influence of the use of superplasticizers. Construction and Building Materials, v. 44, p. 101-109, 2013.

- MUDULI, R.; MUKHARJEE, B. B. Performance assessment of concrete incorporating recycled coarse aggregates and metakaolin: a systematic approach. Construction and Building Materials, v. 233, p. 117223, 2020.

- PACHECO, J. et al. Experimental investigation on the variability of the main mechanical properties of concrete produced with coarse recycled concrete. Construction and Building Materials, v. 201, p. 110-120, 2019.

- PADHI, R. S. et al. Influence of incorporation of rice husk ash and coarse recycled concrete aggregates on properties of concrete. Construction and Building Materials, v. 173, p. 289-297, 2018.

- PEPE, M. A conceptual model for designing recycled aggregate concrete for structural applications Cham: Springer International Publishing, 2015.

- PLAZA, P. et al.Use of recycled coarse and fine aggregates in structural eco-concretes. Physical and mechanical properties and CO2 emissions. Construction and Building Materials, v. 285, p. 122926, 2021.

- POON, C. S.; SHUI, Z. H.; LAM, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Construction and Building Materials, v. 18, n. 6, p. 461-468, 2004.

- RAO, H. S.; REDDY, V. S. K.; GHORPADE, V. G. Influence of recycled coarse aggregate on punching behaviour of recycled coarse aggregate concrete slabs. International Journal of Modern Engineering Research, v. 2, n. 4, p. 2815-2820, 2012.

- REIS, N. et al. Punching behaviour of concrete slabs incorporating coarse recycled concrete aggregates. Engineering Structures, v. 100, p. 238-248, 2015.

- SADATI, S. et al.Shear performance of reinforced concrete beams incorporating recycled concrete aggregate and high-volume fly ash. Journal of Cleaner Production, v. 115, p. 284-293, 2016.

- SAHOO, S.; SINGH, B. Punching shear capacity of recycled-aggregate concrete slab-column connections. Journal of Building Engineering, v. 41, n. 102430, 2021.

- SAHOO, S.; SINGH, B. Recycled aggregate concrete slab punching shear capacity. Structures, v. 24, p. 426–443, 2020.

- SALLES, P. V. et al A importância da segregação do agregado reciclado na resistência e na durabilidade do concreto estrutural. Ambiente Construído, Porto Alegre, v. 21, n. 3, p. 177-196, jul./set. 2021.

- SANTOS, A. A. M.; LEITE, M. B. Avaliação de concretos reciclados com agregado graúdo de concreto dosados pelo método da ABCP modificado. Ambiente Construído, Porto Alegre, v. 18, n. 4, p. 341-359, out./dez. 2018.

- SASANIPOUR, H.; ASLANI, F. Durability properties evaluation of self-compacting concrete prepared with waste fine and coarse recycled concrete aggregates. Construction and Building Materials, v. 236, n. 117540, 2020.

- SEARA-PAZ, S. et al. Flexural performance of reinforced concrete beams made with recycled concrete coarse aggregate. Engineering Structures, v. 156, p. 32–45, 2018.

- SOARES, D. et al. Use of coarse recycled aggregates from precast concrete rejects: Mechanical and durability performance. Construction and Building Materials, v. 71, p. 263-272, 2014.

- SUNAYANA, S.; BARAI, S. V. Flexural performance and tension-stiffening evaluation of reinforced concrete beam incorporating recycled aggregate and fly ash. Construction and Building Materials, v. 174, p. 210–223, 2018.

- TAM, V. W. Y. et al. Methods to improve microstructural properties of recycled concrete aggregate: a critical review. Construction and Building Materials, v. 270, 2021.

- TAM, V. W. Y.; SOOMRO, M.; EVANGELISTA, A. C. J. Quality improvement of recycled concrete aggregate by removal of residual mortar: a comprehensive review of approaches adopted. Construction and Building Materials, v. 288, 2021.

- XIAO, J.; LI, J.; ZHANG, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cement and Concrete Research, v. 35, p. 1187–1194, 2005.

- YANG, Y. F.; HAN, L. H. Experimental behaviour of recycled aggregate concrete filled steel tubular columns. Journal of Constructional Steel Research, v. 62, p. 1310–1324, 2006.

Edited by

-

Editor:

Marcelo Henrique Farias de Medeiros

-

Editores de seção:

Edna Possan e White José dos Santos

Publication Dates

-

Publication in this collection

17 Mar 2025 -

Date of issue

Jan-Dec 2025

History

-

Received

17 Mar 2024 -

Accepted

22 June 2024

Recycled aggregates concrete: mechanical properties and structural performance of slab-column connections

Recycled aggregates concrete: mechanical properties and structural performance of slab-column connections